Communication

Search our website

Clear answers from those who work with data every day

In recent months, we’ve talked a lot about efficiency, data, and process control. But when these topics truly enter the daily routine of a dairy farm, the questions are always the same.

In this article, we’ve collected the most common ones and answered them directly, drawing on the experience of technicians and farms that use these tools every day.

Today, efficiency is not a trend—it’s a necessity. Feed accounts for up to 60% of milk production costs, and we operate within an unstable biological system where small changes can have significant effects on production and profitability. In this context, the margin between an optimal situation and a problematic one is very thin. Talking about efficiency means creating the conditions to maintain this balance over time, acting before issues become visible.

(Answered by: Cristian Rota)

This is one of the most common objections, but it stems from a misunderstanding. You don’t need to measure everything. You need a few key data points—clear, reliable, and collected consistently. The biggest mistake is accumulating information without being able to interpret it. Data analysis should help you understand what’s happening on the farm, not make management more complex. Simplicity is a value, not a limitation.

(Answered by: Cristian Rota)

In feeding management, there are a few key parameters that truly make a difference: dry matter intake, refusal rate, the number of days the feed bunk is empty, and the deviation between the theoretical and the actual ration. These are simple data points, but extremely sensitive ones, because they allow you to immediately detect when management is drifting away from optimal conditions and intervene promptly.

(Answered by: Cristian Rota)

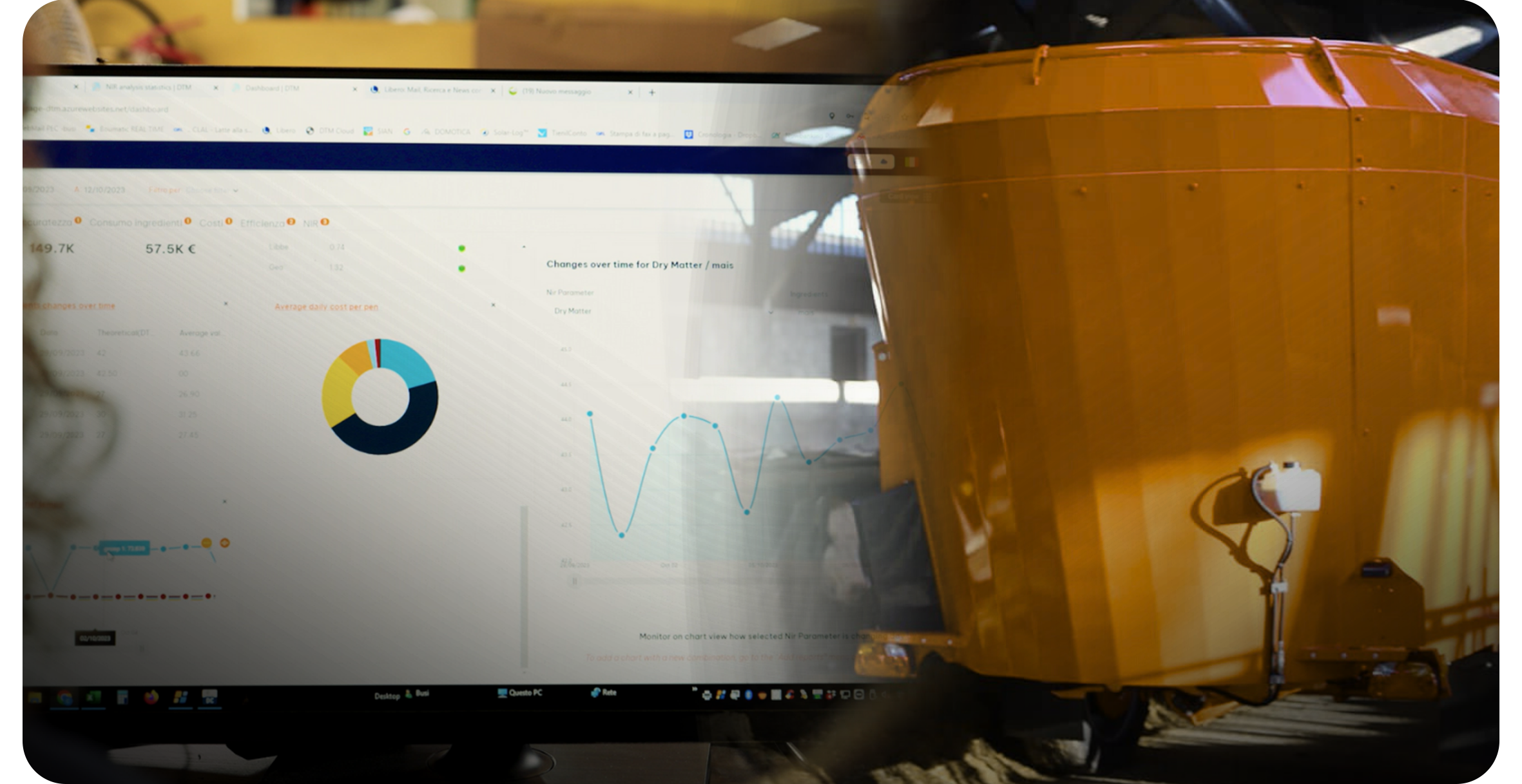

Software does not replace the nutritionist—it supports them. Without reliable data, even the best consultant is working on estimates or perceptions. A tool like DTM allows objective, up-to-date data to be shared and compared over time. This makes discussions more effective and allows you to evaluate whether nutritional strategies are actually working in daily practice.

(Answered by: Cristian Rota; Management of Barbiselle Farm)

Data are not just for management. At Barbiselle, they are used at multiple levels: management for strategic decisions, administration for cost control, the nutritionist to evaluate ration effectiveness, and operators to work more precisely. Value is created when everyone looks at the same numbers and speaks the same language.

(Answered by: Management of Barbiselle Farm)

In the past, yes. Today, no. Previously, we worked with manual Excel files, cross-checks, and spent a lot of time reconstructing data. With DTM, much of the information is entered daily in a structured way, and reports are generated automatically. This reduces operational time and significantly improves the quality of available information. At the end of the month—or the year—the data are already there.

(Answered by: Management of Barbiselle Farm)

The impact is very positive. When operators work with clear objectives and verifiable data, awareness increases and errors decrease. Knowing that the ration must be executed in a specific way—and that deviations are measured—creates accountability and improves work organization. Even the overall working environment benefits.

(Answered by: Adriana Busi, “I Tigli” Farm)

Yes, because feed efficiency has a direct impact on margins. We’re talking about reduced waste, better feed utilization, and greater production stability. Even a small inefficiency, repeated every day, can become a significant annual cost. On the other hand, improving intake and reducing losses means increasing marginal milk—the milk with the highest economic return.

(Answered by: Cristian Rota; Management of Barbiselle Farm)

You start by defining clear objectives. Then you select a few parameters to monitor consistently and build a habit of data analysis. When something doesn’t work, you intervene with training, process adjustments, and team alignment. It’s a continuous process—but it’s also the most effective way to manage the complexity of the modern dairy farm.

(Answered by: Cristian Rota)

This Q&A replaces the discussion that would normally take place in a webinar.

The questions are real, and the answers come from people who work every day in the barn, in the office, and in the field.

Efficiency is not a magic formula, but the result of method, control, and shared data.

Measure. Manage. Multiply.

DTM. We Feed Results.