Communication

Search our website

The benefits of real-time NIR analysis are transforming the way we approach modern farming. In this blog, we explore how real-time insights can drive smarter decisions across the entire agricultural value chain.

At Dinamica Generale, we develop cutting-edge solutions for precision agriculture that help reduce operational costs and minimize environmental impact. Through connected weighing systems, advanced NIR analyzers, and cloud-based software, we offer integrated technologies designed to monitor and optimize every stage of production — from the field to the farm, and all the way to the table.

By harnessing real-time data, farmers and producers can boost productivity, improve resource efficiency, and embrace a more sustainable way of working.

With 60% of production costs tied to animal feed, farmers need reliable tools to ensure consistent and predictable feed quality.

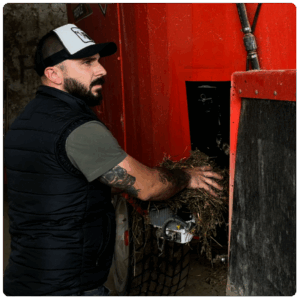

Installed on trailed feed mixers, EVONIR measures dry matter and nutrients (proteins, ADF, NDF, ash, crude fat, starch, etc.) in real-time, enabling:

All collected data is automatically stored and analyzed in DTM cloud, giving farmers complete control over ration components and management based on objective and reliable data.

Real-time analysis with automatic regulation ensures a consistent and balanced ration, following the nutritionist’s formulation. A uniform TMR is essential to optimize dry matter intake and improve productivity in dairy and beef farming. With dedicated calibration curves, the NIR sensor detects when the mixture has reached the desired homogeneity, notifying the farmer via a dedicated app and allowing the automatic stopping of the augers. A color bar on the mixer scale display shows the homogeneity level in real-time, making monitoring easier.

All data is sent to DTM software, allowing remote control by farm managers or nutritionists. Ongoing studies are also evaluating fuel savings thanks to optimized mixing time, delivering economic and environmental benefits.

With real-time analysis, farmers can instantly obtain accurate data on dry matter, starch, proteins, fibers (ADF, NDF), ash, and crude fat, eliminating the need to wait for laboratory results. This information enables nutritionists to quickly adjust feeding strategies, optimizing the ration.

EvoNIR automatically adjusts the amount of water to add to ensure the pre-set dry matter target level in the recipe. Integrated with DTM cloud, the system suggests the exact amount of water needed in real-time to achieve a perfectly balanced ration.

This innovative function allows the analysis of each feed component before loading into the mixer and real-time recipe adjustments via a dedicated app, ensuring precise dry matter loading.

EVONIR calibrations have been validated by university studies, demonstrating strong consistency between NIR data and laboratory analyses on TMR dry matter measurement.

A study conducted at Azienda Agricola Fusi Giovanni (Calcinato – BS, Italy) confirmed excellent TMR uniformity along the entire feeding table. This result is due to the optimized mixing process and real-time NIR analysis, which indicates the exact moment to stop the process.

With rising raw material costs, maximizing on-farm forage utilization and ensuring balanced rations through precise analysis is becoming increasingly important. In some EU countries, regulations are being studied to reduce protein content in animal rations to limit nitrogen emissions and environmental impact. Dinamica Generale will continue to develop innovative technologies to help farmers reduce their environmental footprint without compromising profitability.