Communication

Search our website

In Field

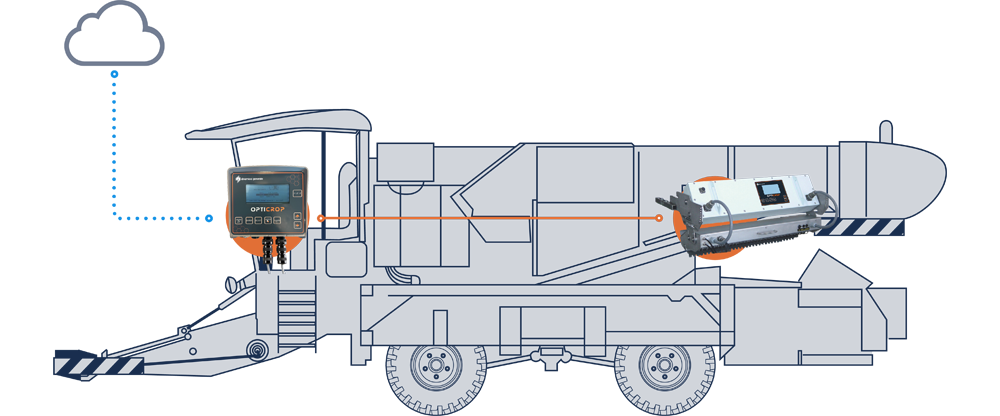

We provide machine-supporting technology to simplify and enhance operations. Our optical sorter uses advanced sensors and software for automated sorting and grading, separating high-quality products from foreign materials or lower-grade items.

The OPTICROP sorter is an advanced optical sorter designed to detect and remove all types of foreign materials from field vegetables. It efficiently eliminates contaminants such as animal matter, metal, cotton stalks, plastic, stones, glass, and wood, ensuring cleaner and higher-quality produce.

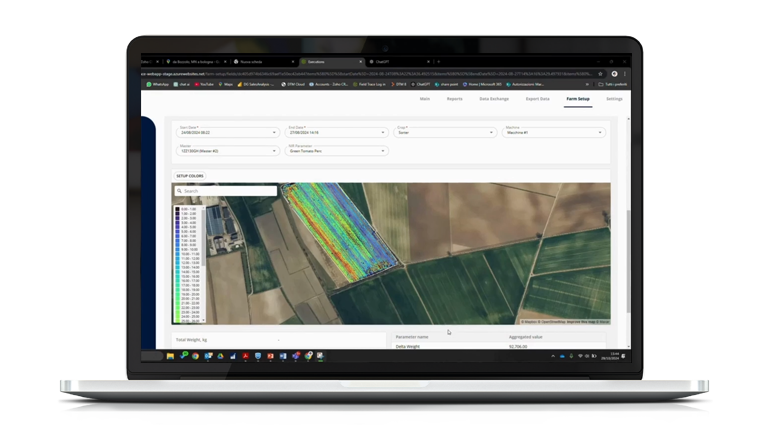

Integrate the data collected in field into FIELD trace software to gain a competitive edge. This integration enables you to save and manage all field data, offering complete traceability and detailed analysis. Optimize your agricultural operations with an accurate, historical overview of your crops, enhancing resource management and operational efficiency.

Please fill out the form below and our team will be happy to answer any questions you may have.