Communication

Search our website

In today’s global dairy industry, efficiency no longer means simply producing more milk. It means controlling costs, measuring performance, and making decisions based on accurate, real-time data. The Barbiselle Farm Case Study from Northern Italy shows how a modern dairy operation can transform feed management into a strategic driver of profitability, sustainability, and operational stability.

Barbiselle Farm is a fifth-generation dairy business located in the Po Valley, one of Europe’s most productive dairy regions. The farm manages around 1,200 animals, including more than 600 lactating dairy cows, producing approximately 8,000 tonnes of milk per year. Milk is delivered to the Grana Padano PDO supply chain through Latteria Soresina, one of Europe’s most important dairy cooperatives.

This scale places Barbiselle among the most advanced mid-to-large dairy farms in Italy and Southern Europe, where precision feeding, feed efficiency, and cost control are critical for long-term competitiveness.

Barbiselle is led by a management team that approaches dairy farming as a modern agribusiness, not just a production unit. In this model, every kilogram of feed, every ton of silage, and every euro invested must be measurable and traceable.

In dairy farms, feed costs typically represent 50–60% of total production costs. Without precise control, even small inefficiencies can translate into hundreds of thousands of euros per year. For this reason, Barbiselle decided to make feeding management the core of its digital transformation strategy.

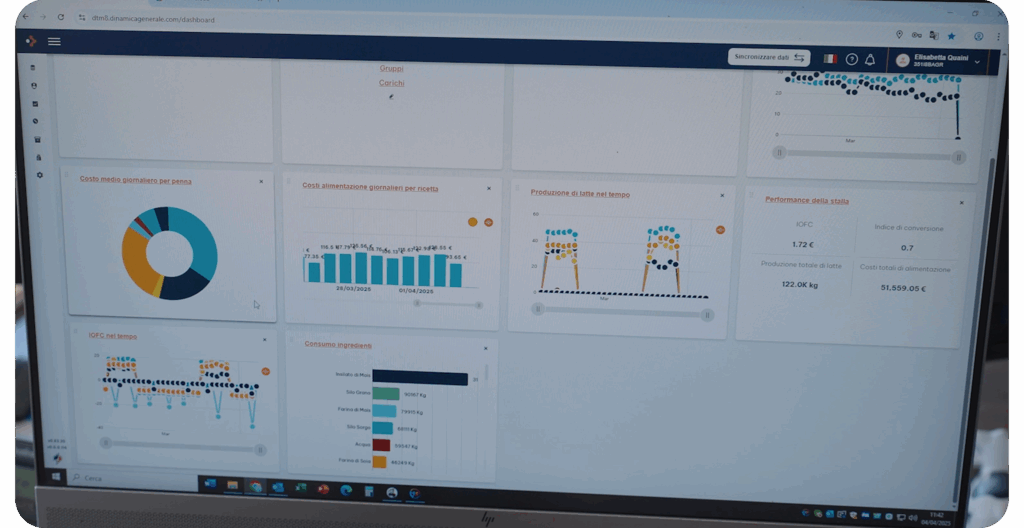

By implementing DTM (Daily TMR Manager), the farm created a centralized feed management and decision-support system that allows continuous monitoring of:

This closed-loop feed management approach allowed Barbiselle to reduce the impact of feed costs from around 70% of total production costs to approximately 50%, creating a major improvement in margin over feed cost (MOFC) and overall farm profitability.

A key strength of the Barbiselle model is the full integration between the barn and the office. The administrative team now manages:

all within the same digital feed management platform.

This enables real-time feed cost control, eliminating manual spreadsheets and delayed reporting. The result is:

For nutritionists and consultants, this means working with verified, real consumption data, not estimates.

DTM also connects directly to daily barn operations. The system tracks:

This creates a transparent and objective monitoring system that improves:

Small loading errors or deviations that previously went unnoticed now become visible and correctable. Over time, this leads to lower feed waste, more stable milk production, and healthier cows.

At Barbiselle, the office is not separate from the barn it is the decision center of the farm. Here, the team:

This data-driven management style allows Barbiselle to anticipate problems instead of reacting to them, creating a more resilient and profitable dairy business.

The Barbiselle case proves that precision feeding is not just about technology — it is about management culture. By transforming feeding into a measured, controlled and optimized process, the farm has achieved:

In today’s competitive dairy industry, data is the most valuable feed ingredient.

Barbiselle represents a replicable model for dairy farms in Italy, France, Germany, Spain, the United States and Canada that want to improve profitability, sustainability and operational control through digital feed management.

Measuring means understanding.

Controlling means improving.

Optimizing means growing.

DTM – We Feed Results.

Click here to watch the full video!