Communication

Search our website

In modern dairy farming, precision feeding is no longer a luxury, it is a necessity.

For years, the primary focus in ration management has been the correction of dry matter (DM) to account for changes in forage moisture.

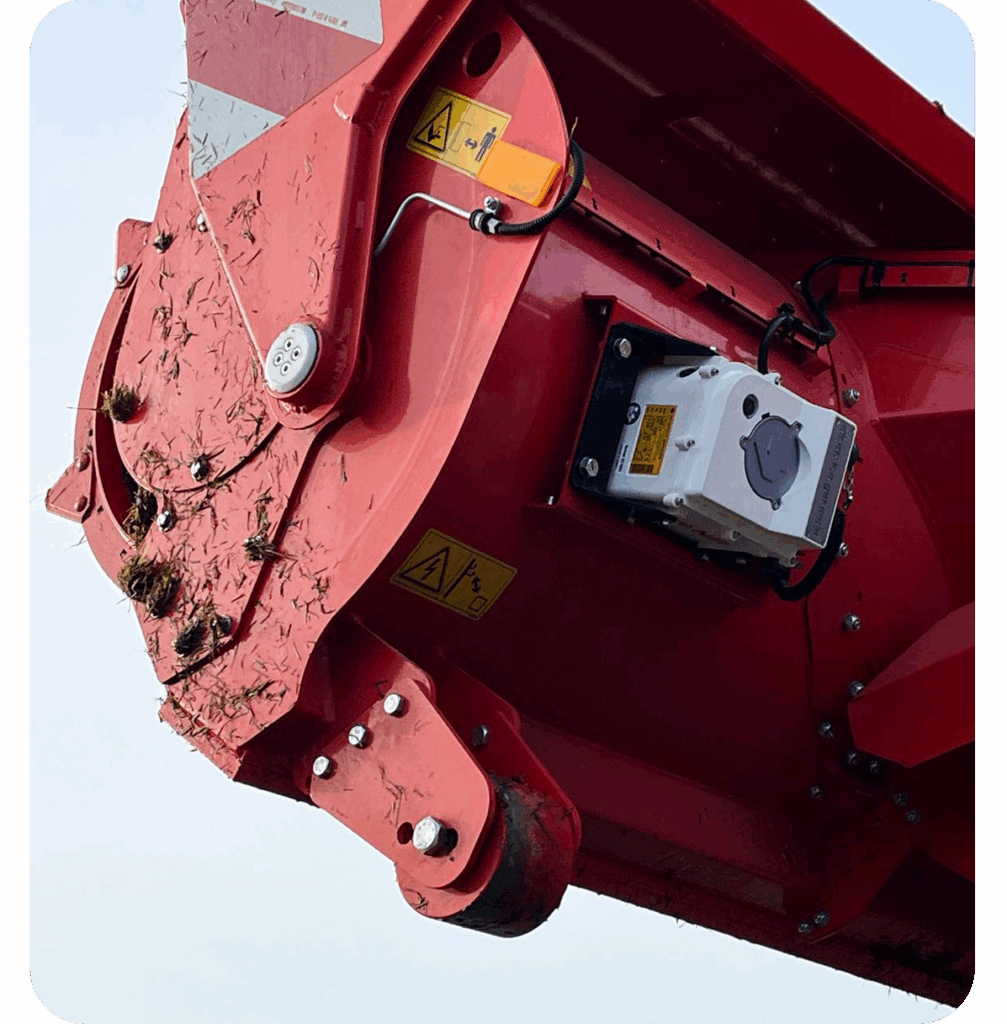

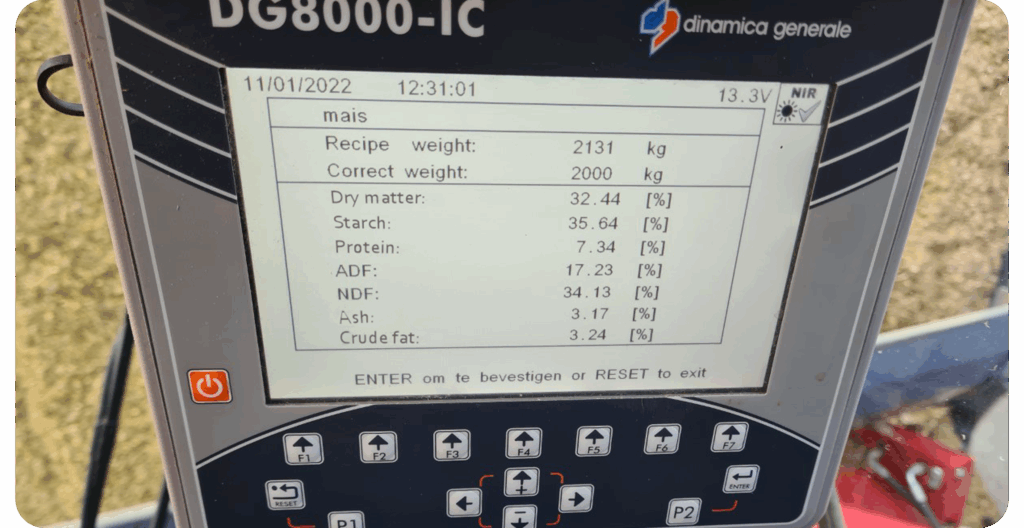

While this is essential, knowing only the DM content tells us how much feed is being loaded, not what the cows are truly eating. With EVONIR sensor is possible to analyze multiple nutritional parameters directly on the mixer wagon, including crude protein (CP), fiber fractions (NDF, ADF), starch, fat, and ash, in addition to DM.

This shift from single-parameter to full-spectrum nutritional control has profound implications for both cow health and farm profitability.

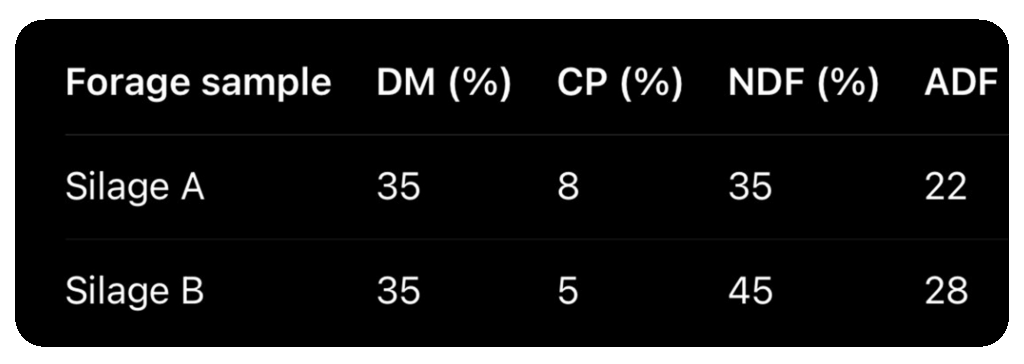

Two corn silages can have the same DM but completely different nutritional values:

If the diet is corrected only for DM, both will be treated as identical, yet Silage B provides less protein, more fiber, and lower digestibility.

Over time, such hidden variations can lead to inconsistent milk yield, reduced feed efficiency, and imbalanced rumen.

Adjusting for dry matter keeps quantity costant. Measuring all nutrients keeps quality constant.

Protein is directly linked to milk protein yield and reproductive performance.

1 % variation in CP content in the total mixed ration (TMR) can alter milk protein concentration by up to 0.1 % (Santos et al., 2018). Unmonitored fluctuations in forage CP lead to either protein deficiency — limiting microbial growth in the rumen — or over-supplementation, increasing feed cost and nitrogen losses (MUN).

By continuously measuring CP, the NIR system allows adjustment of protein sources, maintaining both animal performance and environmental efficiency.

Fiber fractions — Neutral Detergent Fiber (NDF) and Acid Detergent Fiber (ADF) — are the backbone of rumen stability.

Research by Grant & Ferraretto (Cornell PRO-DAIRY, 2020) shows that each 1 % increase in NDF above target can reduce milk yield by 0.7–1.0 kg/day.

Real-time fiber analysis enables consistent NDF/ADF levels and proactive correction of forage variability before it impacts the cow.

Energy supply drives milk volume and component synthesis. However, starch levels can vary by 3–4 % between silage bunkers (Ferraretto et al., 2019). Too little starch depresses milk yield; too much increases the risk of acidosis. Similarly, fat contributes to energy density and milk-fat synthesis. Measuring these parameters ensures energy-balanced rations every day, reducing metabolic stress and stabilizing production.

Ash represents the mineral and soil contamination of forage. Elevated ash values indicate dirt or sand inclusion, which lowers digestibility and may cause mechanical wear in mixers.

According to Undersander (UW Extension), each 1 % increase in ash can reduce digestibility by 0.5 %.

On-board NIR instantly flags contaminated loads, helping maintain forage quality standards.

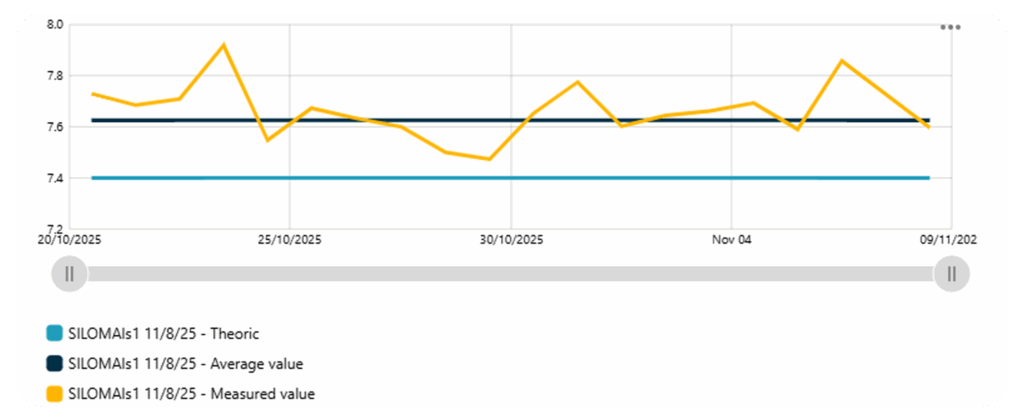

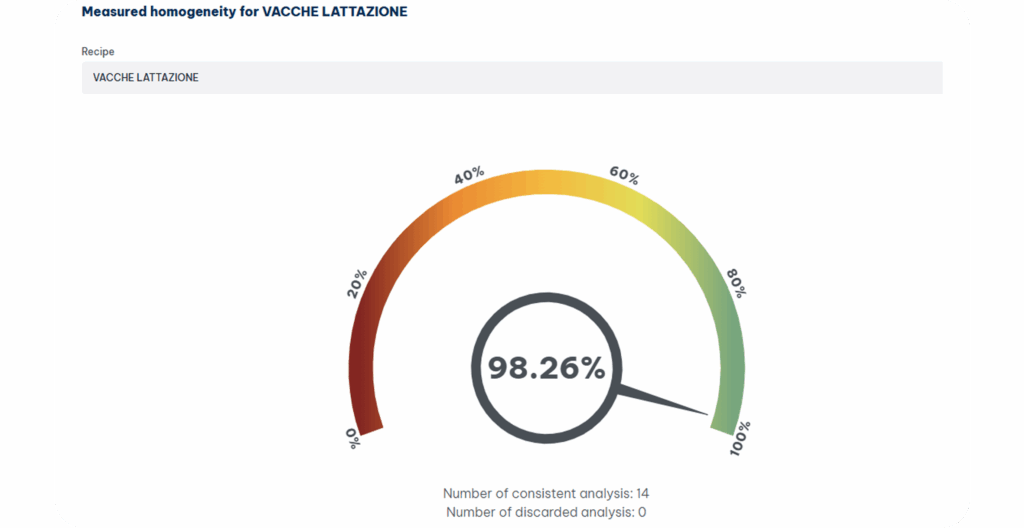

Even with the same ingredients, daily variation in nutrient composition can cause measurable performance losses. Bach et al. (2005) reported that inconsistent TMR nutrient profiles resulted in 1.5 L less milk per cow per day compared to consistent feeding. EVONIR analyzer monitors the homogeneity of the mix and maintains stable nutrient delivery to every animal group.

Cabrera et al. (2018, J. Dairy Sci.) demonstrated that each 1 % error in ration nutrient content can affect income-over-feed cost (IOFC) by €15–25 per cow per month.

By minimizing nutrient variation, farmers gain:

These results translate into higher profitability, better sustainability, and healthier herds.

Unlike standalone sensors that provide only DM correction, Dinamica Generale’s EVONIR integrates seamlessly with the DTM Cloud software.

Each nutrient measurement is stored, analyzed, and compared over time, creating a complete traceability system for forage quality and ration performance.

Farmers and nutritionists can then make data-driven adjustments that improve both production efficiency and environmental outcomes.

Dry matter correction is the first step toward precision feeding but multi-parameter NIR analysis is what truly defines it.

By simultaneously measuring protein, fiber, energy, and mineral content, farmers can formulate rations that are nutritionally stable, biologically balanced, and economically optimized.